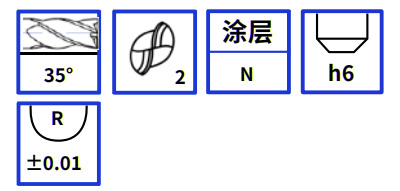

鋁以及鋁合金、銅以及銅合金、非金屬合金加工銑刀

使用范圍較廣,可加工有色金屬類的材料。

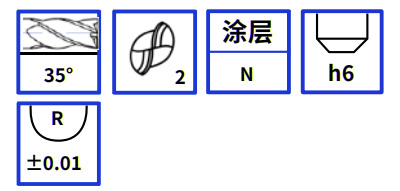

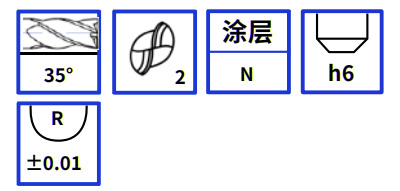

45 度螺旋角與深槽設計,排屑性非常好。

中加工或粗加工時,作業效率高。

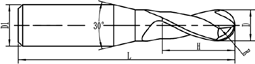

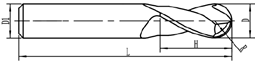

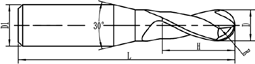

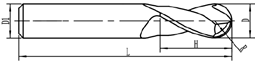

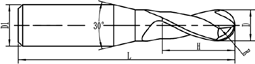

示意圖

刃徑公差

|

刃徑公差

|

|

0.2 ≤ D ≤ 3

|

0~-0.01

|

|

3 < D ≤ 12

|

0~-0.02

|

|

12 < D

|

0~-0.03

|

訂貨信息

|

訂貨號

Order no

|

基本尺寸(mm)

Basic size

|

齒 數

Total number of teeth

|

|

刃徑 D

Dia

|

R角R

Angle

|

刃長 H

Blade length

|

柄徑 D1

Shank Diameter

|

總長 L

Overall Length

|

|

NMR102N-D0.2R0. 1-0.4-D4-50

|

0.2

|

0.1

|

0.4

|

4

|

50

|

2

|

|

NMR102N-D0.3R0. 15-0.6-D4-50

|

0.3

|

0.15

|

0.6

|

4

|

50

|

2

|

|

NMR102N-D0.4R0.2-0.8-D4-50

|

0.4

|

0.2

|

0.8

|

4

|

50

|

2

|

|

NMR102N-D0.5R0.25- 1-D4-50

|

0.5

|

0.25

|

1.0

|

4

|

50

|

2

|

|

NMR102N-D0.6R0.3- 1.2-D4-50

|

0.6

|

0.3

|

1.2

|

4

|

50

|

2

|

|

NMR102N-D0.7R0.35- 1.4-D4-50

|

0.7

|

0.35

|

1.4

|

4

|

50

|

2

|

|

NMR102N-D0.8R0.4- 1.6-D4-50

|

0.8

|

0.4

|

1.6

|

4

|

50

|

2

|

|

NMR102N-D0.9R0.45- 1.8-D6-50

|

0.9

|

0.45

|

1.8

|

6

|

50

|

2

|

|

NMR102N-D1R0.5-2-D4-50

|

1.0

|

0.5

|

2

|

4

|

50

|

2

|

|

NMR102N-D1.5R0.75-3-D4-50

|

1.5

|

0.75

|

3

|

4

|

50

|

2

|

|

NMR102N-D2R1-4-D4-50

|

2.0

|

1.0

|

4

|

4

|

50

|

2

|

|

NMR102N-D2.5R1.25-5-D4-50

|

2.5

|

1.25

|

5

|

4

|

50

|

2

|

|

NMR102N-D3R1.5-6-D4-50

|

3.0

|

1.5

|

6

|

4

|

50

|

2

|

|

NMR102N-D3.5R1.75-7-D4-50

|

3.5

|

1.75

|

7

|

4

|

50

|

2

|

|

NMR102N-D4R2-8-D4-50

|

4.0

|

2.0

|

8

|

4

|

50

|

2

|

|

NMR102N-D4.5R2.25-9-D6-50

|

4.5

|

2.25

|

9

|

6

|

50

|

2

|

|

NMR102N-D5R2.5- 10-D6-50

|

5.0

|

2.5

|

10

|

6

|

50

|

2

|

|

NMR102N-D5.5R2.75- 11-D6-50

|

5.5

|

2.75

|

11

|

6

|

50

|

2

|

|

NMR102N-D6R3- 12-D6-50

|

6.0

|

3.0

|

12

|

6

|

50

|

2

|

|

NMR102N-D7R3.5- 14-D8-60

|

7.0

|

3.5

|

14

|

8

|

60

|

2

|

|

NMR102N-D8R4- 16-D8-60

|

8.0

|

4.0

|

16

|

8

|

60

|

2

|

|

NMR102N-D9R4.5- 18-D10-75

|

9.0

|

4.5

|

18

|

10

|

75

|

2

|

|

NMR102N-D10R5-20-D10-75

|

10.0

|

5.0

|

20

|

10

|

75

|

2

|

|

NMR102N-D12R6-24-D12-75

|

12.0

|

6.0

|

24

|

12

|

75

|

2

|

|

NMR102N-D14R7-28-D14-75

|

14.0

|

7.0

|

28

|

14

|

75

|

2

|

|

NMR102N-D16R8-32-D16- 100

|

16.0

|

8.0

|

32

|

16

|

100

|

2

|

|

NMR102N-D18R9-36-D18- 100

|

18.0

|

9.0

|

36

|

18

|

100

|

2

|

|

NMR102N-D20R10-40-D20- 100

|

20.0

|

10.0

|

40

|

20

|

100

|

2

|